From patient to innovator: Student creates orthopaedic cast to support NHS after spinal injury

By Chris Birkle | Published on 10 June 2025

Categories: Press office; School of Architecture, Design and the Built Environment;

A design student who broke his back during a hockey match and underwent months of rehabilitation has developed an advanced orthopaedic cast that would significantly improve patient recovery while alleviating pressure on the National Health Service (NHS).

Jake Inglis, 22, sustained a T12 vertebral fracture at the age of 17 while playing for a Scottish club team. Following several months in a wheelchair and intensive physiotherapy, he returned to sport just six months after the injury. This life-changing experience became the foundation for a user-led medical innovation aimed at transforming fracture care.

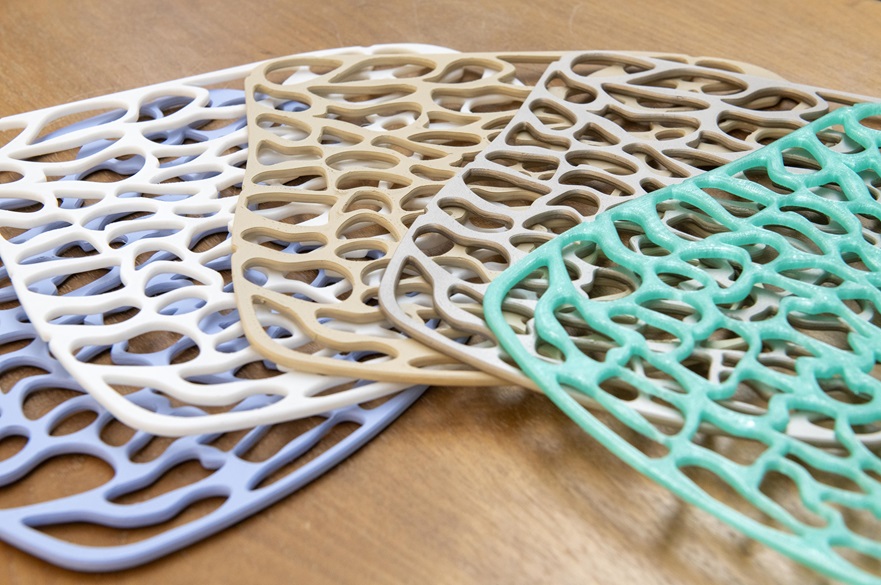

Currently in his final year of the BSc Product Design programme at Nottingham Trent University (NTU), Jake has designed a fully customisable, injection-moulded lattice forearm cast. The device is lightweight, water-resistant, and easily removable, enabling patients to shower and manage hygiene more effectively during recovery.

The cast, named Morphopaedics, is formed directly on the patient’s arm by heating it and shaping it in situ. As swelling reduces, the cast allows for micro-adjustments—offering a dynamic, patient-responsive solution that contrasts with the static nature of traditional plaster casts.

Made from Nylon 66 and engineered with a lattice structure to optimise support while minimising bulk, the cast is also radiolucent, allowing X-rays to be taken without removal. This reduces the need for repeated cast replacements and enhances the continuity of care.

Additional clinical benefits include its hypoallergenic breathable properties, its recyclability, and its smoothed edges, which improve comfort and reduce the risk of skin irritation.

“Being immobilised and going through rehab gave me a deep understanding of the frustration and isolation that patients feel,” said Jake, from Trinity in Edinburgh, who is studying in the School of Architecture, Design and the Built Environment.

A close-up of Jake's design

“Being an athlete and who is used to moving your body all of the time, to becoming unable to move altogether, was incredibly frustrating for me.

“So this cast was born out of that empathy, and a belief that we can do better – both for patients and for the healthcare system.”

Morphopaedics has received positive feedback from healthcare professionals, who highlighted its potential to streamline treatment protocols. The system could reduce the frequency of cast changes, lower demand for specialist staff, and significantly decrease clinic storage requirements—up to 40 casts can be stored in the space occupied by five traditional models.

A 3D-printed prototype has already been built and tested, with the design now entering the injection-moulding phase. Jake is currently in the process of registering the design and securing trademark protection for the Morphopaedics brand. He plans to refine the product further during an upcoming Master’s degree.

“There’s a huge opportunity here to modernise a process that hasn’t changed in decades,” Jake added. “Medical imaging has advanced exponentially – casting hasn’t. I want to change that.”

His work is being featured at NTU’s 2025 Student Showcase, one of the largest exhibitions of graduating art and design talent in the UK.

Dr Joseph Stewart, Course Leader for BSc Product Design at NTU, commented: “Jake has shown how simple design skills can radically modernise the way people are treated for common injuries such as fractures. His design would not only lead to greater efficiencies for the NHS, but a better experience for patients which would help improve their recovery times and overall wellbeing.”

Notes for Editors

Press enquiries please contact Chris Birkle, Public Relations Manager, on telephone +44 (0)115 848 2310, or via email.

Nottingham Trent University (NTU) has been named UK ‘University of the Year’ five times in six years, (Times Higher Education Awards 2017, The Guardian University Awards 2019, The Times and Sunday Times 2018 and 2023, Whatuni Student Choice Awards 2023) and is consistently one of the top performing modern universities in the UK.

It is the 3rd best modern university in the UK (The Times and Sunday Times Good University Guide 2023). Students have voted NTU 1st in the UK for student employability (Uni Compare 2025)

NTU is the 5th largest UK institution by student numbers, with over 40,000 students and more than 4,400 staff located across six campuses. It has an international student population of almost 7,000 and an NTU community representing over 160 countries.

NTU owns two Queen’s Anniversary Prizes for outstanding achievements in research (2015, 2021). The first recognises NTU’s research on the safety and security of global citizens. The second was awarded for research in science, engineering, arts and humanities to investigate and restore cultural objects, buildings and heritage. The Research Excellence Framework (2021) classed 83% of NTU’s research activity as either world-leading or internationally excellent.

NTU was awarded GOLD in the national 2023 Teaching Excellence Framework (TEF) assessment, as it was in 2019.

NTU is a top 10 for sport (British Universities and Colleges Sport league table 2023).

NTU is the most environmentally sustainable university in the UK and second in the world (UI Green Metric University World Rankings, 2023).