Researchers KNIT satellite antenna for outer space

NTU works with space technology business to create new generation of knitted satellites

By Chris Birkle | Published on 19 February 2018

Categories: Press office; Research;

Researchers from the Advanced Textiles Research Group (ATRG) are knitting antenna reflectors from high performance gold wire to help send and receive radio signals in orbit.

The project - in collaboration with space technology business Oxford Space Systems – is centred on the antennas being lightweight and deployable.

The aim is for the knitted antenna to open like an umbrella and form a parabolic shape to reflect high frequency radio signals.

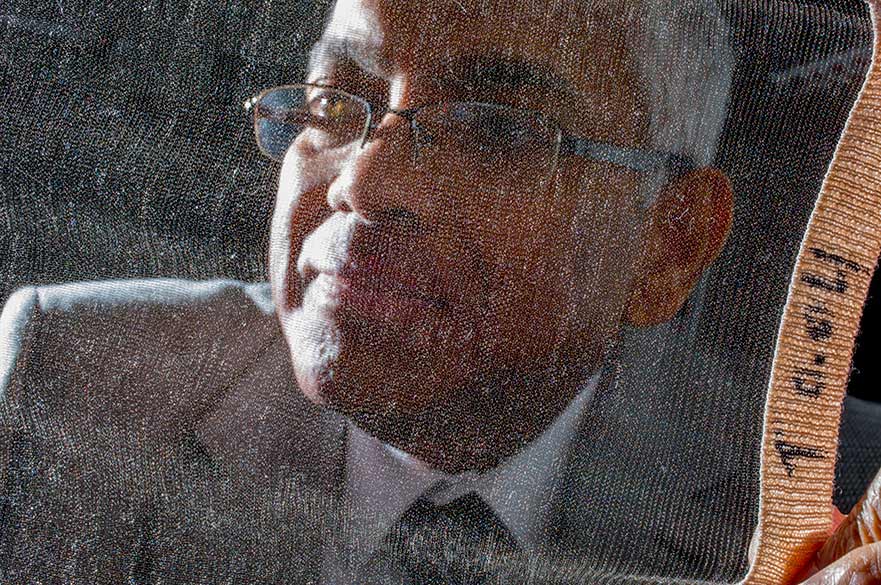

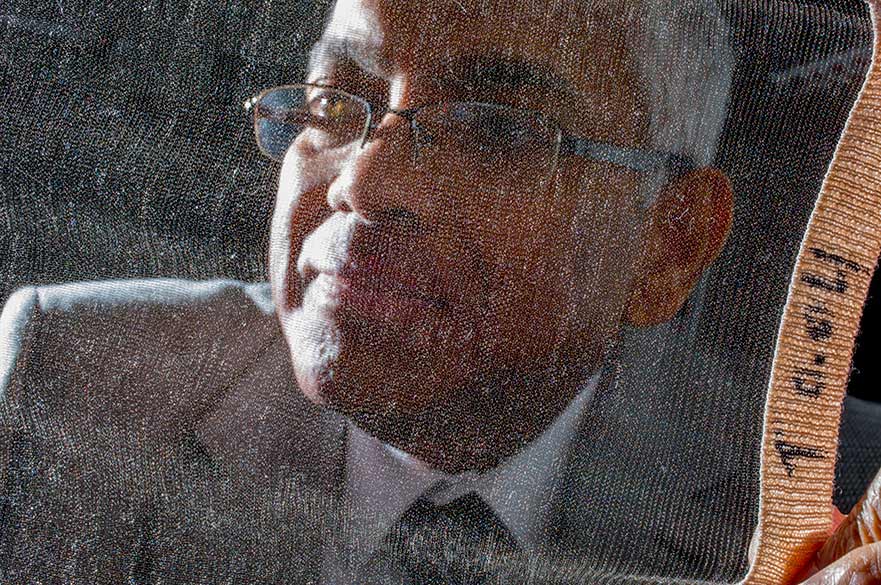

“Few people associate knitting with high-end space technology,” said project lead Professor Tilak Dias, Head of the ATRG in Nottingham Trent’s School of Art & Design.

“However due to the advancements in knitting technology we can now knit an antenna which is extremely lightweight, cost-effective and robust enough to withstand solar radiation.

“This is a very exciting research project. And by working with Oxford Space Systems, we hope it will lead to the UK becoming a manufacturing centre for similar high-performance space materials.”

A video interview with Prof Tilak Dias and researcher Will Hurley

Professor Tilak Dias with a piece of knitted mesh

The wire – which is less than half a millimetre thick – is gold-plated to make it more resistant to the harsh operational environment of space.

By using advanced knitting techniques, the researchers aim to produce membrane-like structures that can be shaped into 3-D parabolas resembling the ideal reflector antenna geometry.

“By making a satellite antenna as lightweight as possible, we can save on valuable materials and make the technology easier to deliver to space,” said researcher and senior lecturer Will Hurley.

“And by applying novel knitting techniques, we can eradicate waste from the manufacturing process and save on valuable resources.

“When you consider that knitted gold wire can cost hundreds of thousands of pounds per square metre, waste is something we have to be very mindful of.”

The project is funded under Innovate UK’s: Materials & Manufacturing Round 2 Initiative.

Dr Juan Reveles, Chief Technology Officer at Oxford Space Systems, said: “Our partnership with NTU will allow us to explore novel manufacturing techniques to develop proprietary light weight and cost competitive reflector antenna technology and will position the UK favourably to exploit the commercial opportunities offered by the buoyant New Space market.”

Notes for Editors

Press enquiries please contact Chris Birkle, Public Relations Manager, on telephone +44 (0)115 848 2310, or via email; or Dave Rogers, Public Relations Manager, on telephone +44 (0)115 848 8782, or via email.

Nottingham Trent University

Nottingham Trent University was named Modern University of the Year in the Times and Sunday Times Good University Guide 2018. The award recognises NTU for its strong student satisfaction, quality of teaching, overall student experience and engagement with employers.

Nottingham Trent University (NTU) is one of the largest UK universities with nearly 28,000 students and more than 3,500 staff across four campuses, contributing £496m to the UK economy every year. It is one of the most environmentally-friendly universities, containing some of the country’s most inspiring and efficient award-winning buildings.

The University is passionate about creating opportunities and its extensive outreach programme is designed to enable NTU to be a vehicle for social mobility. The University is the sixth biggest recruiter of students from disadvantaged backgrounds in the country and 95.6% of its graduates go on to employment or further education within six months of leaving.

NTU is home to world-class research, winning The Queen’s Anniversary Prize in 2015 - the highest national honour for a UK university. The prize recognised pioneering projects to improve the detection of weapons and explosives in luggage, enable safer production of powdered infant formula and combat food fraud.

With an international student population of approximately 2,600 from around 100 countries, the University prides itself on its global outlook and seeks to attract talented students and staff from across the world

Oxford Space Systems

Oxford Space Systems is a venture capital backed space technology business that is pioneering the development of next-generation deployable antennas and structures for the global space industry. It’s achieving this by combining new proprietary materials with traditional flight proven materials, and often uses origami design techniques.

The company set two records for the space industry: the fastest time from a company formation to a product successfully deployed on orbit (<30 months) with its AstroTube™ boom – the world’s longest retractable boom system.

Founded in September 2013, OSS has successfully completed three rounds of over-subscribed venture capital funding from both UK and US investors.

OSS has won numerous awards such as the UK’s Best Tech Start-Up 2015 at the British Engineering Excellence Awards and the Best Investment in a UK Manufacturing Business 2015 from the UK Business Angels Association.

OSS is based at the UK’s Space Cluster at the Harwell Campus, Oxfordshire, where it has access to world-class test facilities and expertise required to validate its products and technologies. OSS moves into its own custom facility in Q2, 2018 as part of its growth and expansion.

The company uses its proprietary materials, such as flexible composites along with origami techniques to produce structures such as novel antennas and boom systems that are lighter, less complex and more stowage efficient than those in current commercial demand.