University invents world’s first invisibility cloak

Researchers at Nottingham Trent University have invented the world’s first invisibility cloak – and experts say it could be the next big thing in fashion.

By Chris Birkle | Published on 1 April 2019

Categories: Press office;

- This was an April Fools’ Day joke. But to read about our equally amazing smart textiles research, click here -

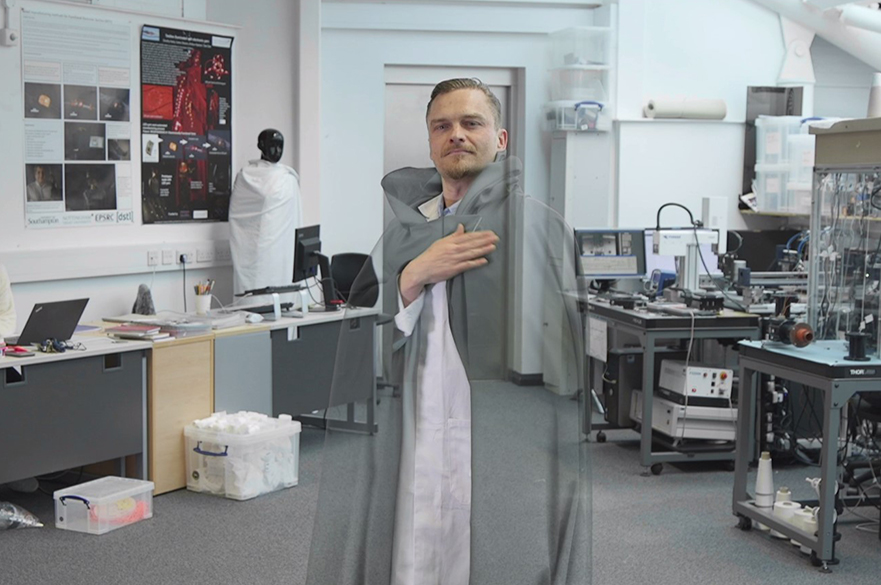

Researchers at Nottingham Trent University have invented the world’s first invisibility cloak – and experts say it could be the next big thing in fashion.

A team from the Advanced Textiles Research Group have embedded miniaturised semiconductors in the yarn of clothes which are so small that they cannot be felt or seen by the wearer.

A prototype cloak has been embedded with 250 micro-controllers, which act like tiny cameras, and detect the ambient light spectrum surrounding the wearer.

This light spectrum is then projected via 3,000 miniaturised photonic devices, also embedded in the cloak, which show the image that is captured on the other side with pinpoint accuracy.

The effect is that the cloak is at all times projecting the images which surround it, giving an illusion of invisibility.

The technology – named i-Yarn – is the first of its kind and has been patented by the university, allowing the institution to transparently reveal the technology today.

Senior Researcher Richard Arm, of the School of Art & Design, said: “This technology proves that an invisibility cloak – the likes of which we have seen in Harry Potter films – is finally within the fashion industry’s sights.

“By embedding hundreds of tiny photo-reactive and photo-emitting devices in yarn, we are able to capture and project live images in a piece of clothing, creating an illusion of invisibility.

“This is a major step forward – a world first - and the potential for fashion is clear to see.”

Senior Researcher

The university – which has been developing the technology as part of a two year research project – is in discussions with industry about how the i-Yarn can be brought to market. Manufacturer Radial Of Ploys is at an advanced stage of negotiations with the research team.

Chris Davison, Business Development Manager for the School of Art & Design, said: “This is all about innovation. The i-Yarn is something that the world has never seen before.

“From a fashion point of view, the potential is huge. With invisible clothes, you will never again be seen in the wrong thing, in the wrong place, at the wrong time.

“We’re already in talks with a range of companies which are very excited about it. I cannot wait to see this technology on the catwalks of London and Paris.”

Notes for Editors

Press enquiries please contact Chris Birkle, press officer, on telephone +44 (0)115 848 2315, or via email, or Dave Rogers, head of communications, on telephone +44 (0)115 848 8782, or via email

About Nottingham Trent University

Nottingham Trent University was named University of the Year 2017 at the Times Higher Education Awards and Modern University of the Year in The Times and Sunday Times Good University Guide 2018. The award recognises NTU for its strong student satisfaction, quality of teaching, overall student experience and engagement with employers.

Nottingham Trent University (NTU) has been awarded the highest, gold, rating in the Government’s Teaching Excellence Framework for its outstanding teaching and learning.

The University is passionate about creating opportunities and its extensive outreach programme is designed to enable Nottingham Trent to be a vehicle for social mobility. NTU is the sixth biggest recruiter of students from disadvantaged backgrounds in the country and 95.6% of its graduates go on to employment or further education within six months of leaving.

NTU is home to world-class research, winning The Queen’s Anniversary Prize in 2015 - the highest national honour for a UK university. It recognised the University’s pioneering projects to improve weapons and explosives detection in luggage, enable safer production of powdered infant formula and combat food fraud.