#NTUDEGREESHOW Spotlight: Olivia Killeya

This week's Spotlight piece features BSc (Hons) Product Design student Olivia Killeya.

By Chloe Subitte | Published on 3 May 2019

Categories: Current students; School of Architecture, Design and the Built Environment;

In the run-up to the Art and Design Degree Show, we will be sharing a series of student projects from across the 26 participating courses through #NTUDEGREESHOW Spotlights.

OVB Arm Brace

Richard Kershaw – an experience road cyclist – suffered a severe brachial plexus injury on his right-hand side, after a cycling accident in 2017. This left Richard’s right arm partially paralysed, with only the ability to grip with his right hand.

An ‘off-the-shelf’ NHS brace allowed Richard to return to cycling, however a brace that was durable, robust and fit for purpose was needed. Throughout my project, I have noticed a lack of sport specific orthotic devices on the market, such as braces for those who suffer from life changing upper limb injuries.

I was able to undertake various research, including observations of Richard cycling with his NHS brace to identify areas of improvements. I also chatted with Richard to specifically understand more about his process of recovery and what he wanted from a new design.

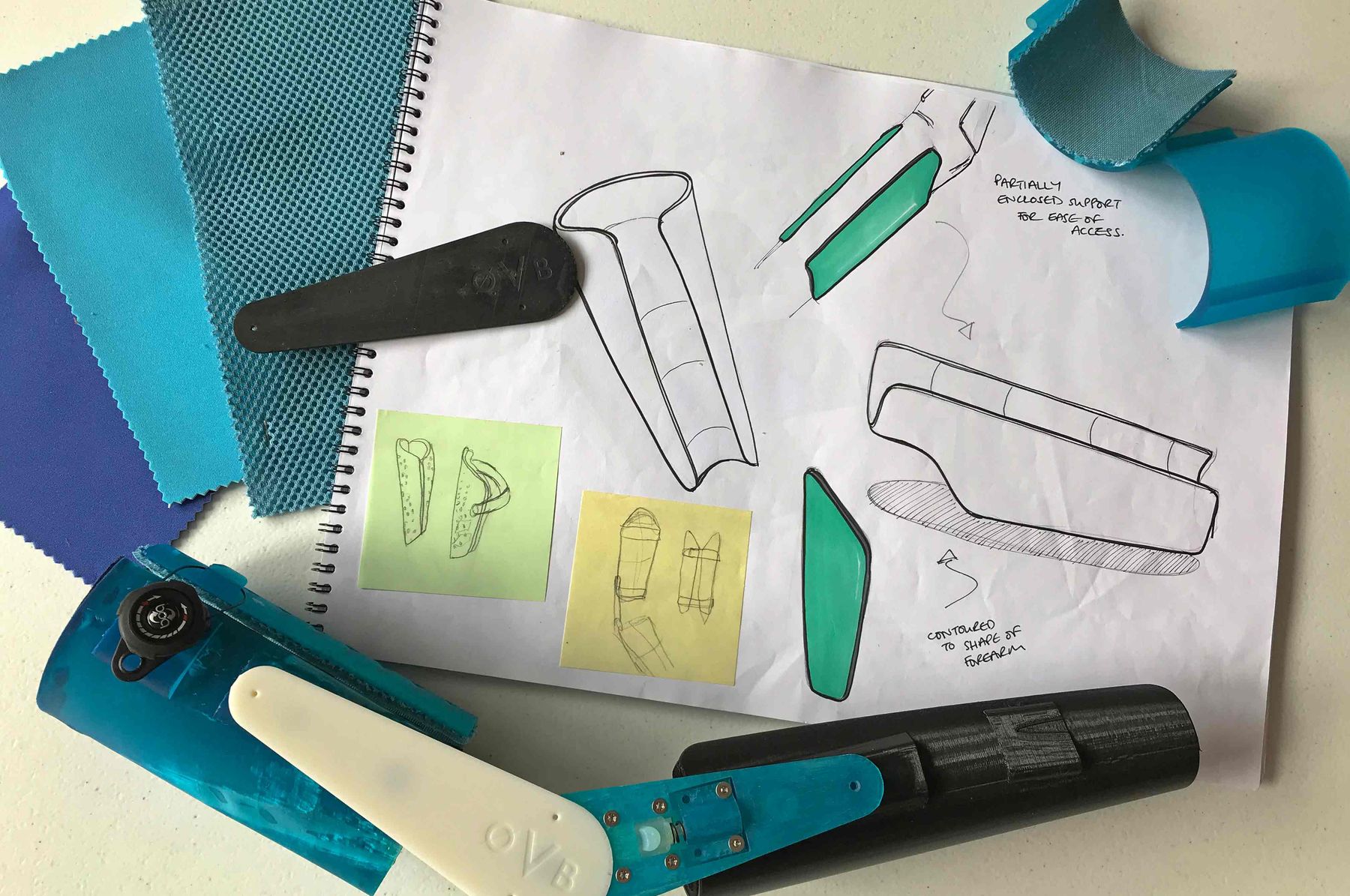

My design process started by producing sketch concepts using similar orthotic devices as inspiration, as well as gaining Richards’s feedback and comments, on how to improve the support given to the arm and the choice of fastening.

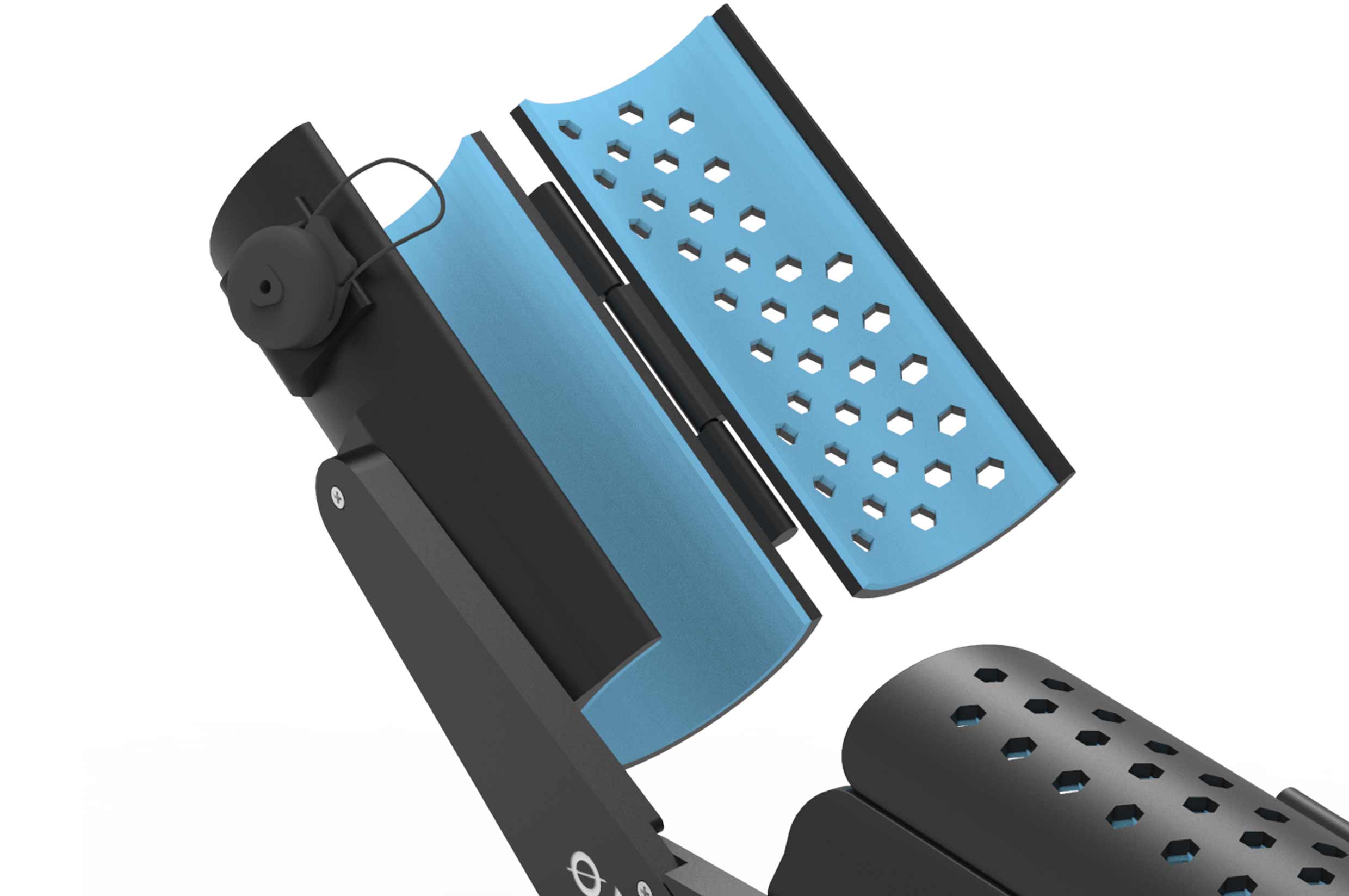

My final outcome consists of 3D printed arm supports lined with foam – which allows Richard to rotate his forearm in 10-degree increments, and therefore adjust his position on the bike whilst cycling.

Now in the prototyping and testing stages, I have produced multiple models to test each element and show to Richard for feedback. Richard has been able to fit test the supports and I have made the necessary tweaks to improve the fit and comfort.

As this is my first time using 3D printing, I have found it very beneficial as custom parts could be produced, tested and altered if necessary to then go try and fit again with Richard.

Olivia Killeya

Find out more about the BSc (Hons) Product Design Degree Show here.