Miniature biosensor can monitor condition of serious wounds

A new biosensor capable of accurately monitoring the condition of a chronic wound has been developed by a team at Nottingham Trent University and Nottingham University Hospitals NHS Trust.

By Dave Rogers | Published on 31 August 2022

Categories: Press office; Research; School of Science and Technology;

Wounds represent a burgeoning health care issue affecting thousands of patients in all health and social care settings, leading to a spiralling expenditure on an already overloaded health system.

One of the most urgent needs in wound management is the development of systems that allow clinicians to identify the early progression or deterioration of wounds.

The team of engineers and clinical academics at NTU and NUH says the aim is for the technology to be embedded into dressings so that they do not need to be continually removed and replaced to assess how a wound is healing.

They say that in time the technology – a textile-based printed protein sensor – could help to reduce the risk of patients becoming seriously ill, prevent amputation, and save time and money.

Patients can not currently assess the condition of a wound and health professionals are required to remove the dressing to assess it visually.

This can take time as patients require an appointment and removing the dressing too soon risks lengthening the healing process, making scarring worse, or introducing an infection. The dressing also needs replacing each time the wound is checked, which takes more time.

Chronic wounds include wounds as a result of serious injury or trauma, ulcers, pressure sores or through diseases such as diabetes.

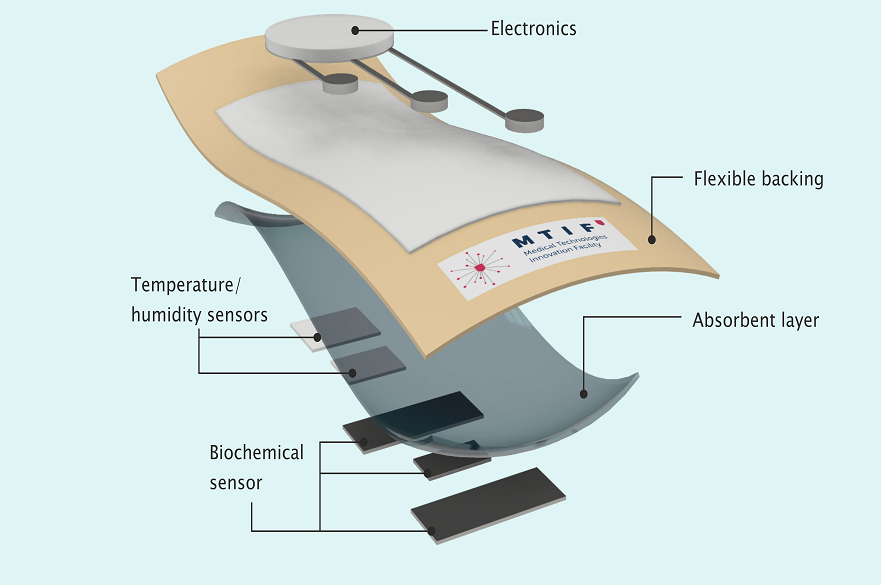

The new sensor, which is printed onto fabric would be integrated in the dressing, uses electrodes to analyse the concentration of specific proteins in a wound constantly and in real time.

Using app-based technology, the patient would be able to take a reading and receive some simple information by holding a smartphone near to the dressing. They would then be able to book an appointment, if necessary, so that it can be checked by a clinician.

The miniature sensor, which is lightweight and flexible, would be able to determine whether the dressing required changing, can come off completely or if the wound has an infection.

The cost of treating wounds is thought to account for about least three percent of the total healthcare expenditure in most developed countries and since 2018 it is estimated that the UK is managing about 3.8 million patients with a wound in a clinical setting annually.

It was also estimated that health services in 2012 spent more than £5 billion on costs associated with wound care management.

The researchers say that now the technology is established, the next step will be to work with consultant clinicians and digital technology providers to look at moving it into commercial products.

The project also involves industry partner Kymira.

“There is currently no way to monitor the condition of a wound without booking an appointment, having the dressing removed and taking a look,” said researcher Dr Yang Wei, an expert in electronic textiles and electronic engineering in Nottingham Trent University’s School of Science and Technology.

He said: “The sensor analyses chemical biomarkers to give an indication of whether a wound is healing or not and could help remove a range of risks associated with continuous and laborious removal and replacement of dressings. As well as improving patients’ quality of life, it could speed up the healing process, help to avoid infection and avoid worsening scars by removing dressings while they are still forming.

“Wounds can take months to heal and this could potentially be of great benefit to many people. It enables patients to monitor the wound themselves and reducing worrying about their condition in addition to saving time and money in the process.

“It would also be consistent and quantifiable and help to remove the subjective nature of assessing a wound.”

Professor John Hunt of NTU’s Medical Technologies Innovation Facility, who was also involved in the study, said: “This research addresses a clear need for improved treatments. The approach will not only deliver on improved wound healing, it will reduce patient worries, reduce visits either at home or with the healthcare provider and enable people to manage their health and maintain greater independence.

“We are delighted to be facilitating this research in MTIF as digital health solutions are a key part of the world delivering on future health needs.”

Professor Christine Moffatt CBE, who is professor of skin integrity at NUH, described these developments as having a massive potential to change the lives of thousands of people suffering with wounds and improve the delivery of effective care.

NUH is one of the largest acute hospitals in the UK and has a strategic plan for skin integrity in which developments of new technology such as this play a prominent role.

Professor Moffatt said she looked forward to continuing this partnership and promoting the new technologies both nationally and at an international level.

The Nottingham Trent University team’s work is published in the journal Scientific Reports.

Notes for Editors

Press enquiries please contact Dave Rogers, Public Relations Manager, on telephone +44 (0)115 848 8782, or via email.

Nottingham Trent University (NTU) received the Queens Anniversary Prize for Higher and Further Education in 2021 for cultural heritage science research. It is the second time that NTU has been bestowed the honour of receiving a Queen’s Anniversary Prize for its research, the first being in 2015 for leading-edge research on the safety and security of global citizens.

The Research Excellence Framework (2021) classed 83% of NTU’s research activity as either world-leading or internationally excellent. 86% of NTU’s research impact was assessed to be either world-leading or internationally excellent.

NTU was awarded Outstanding Support for Students 2020 (Times Higher Education Awards). It was the University of the Year 2019 (Guardian University Awards, UK Social Mobility Awards), Modern University of the Year 2018 (Times and Sunday Times Good University Guide) and University of the Year 2017 (Times Higher Education Awards).

NTU is the 5th largest UK institution by student numbers, with over 33,000 students and more than 4,000 staff located across five campuses. It has an international student population of 4,000 and an NTU community representing around 160 countries.

In the past 15 years, NTU has invested £450 million in tools, technology and facilities.

NTU is in the UK’s top 10 for number of applications and ranked first for accepted offers (2019 UCAS UG acceptance data) It is also among the UK’s top five recruiters of students from disadvantaged backgrounds.

75% of NTU students go on to graduate-level employment or graduate-entry education / training within fifteen months of graduating (Guardian University Guide 2021).

NTU is 4th globally (and 3rd in the UK) for sustainability in the 2021 UI Green Metric University World Rankings (out of more than 900 participating universities).