Metal workshop

Based in the Maudslay building, our metal workshop allows students to work with metal materials to develop prototypes and test ideas with expert supervision from our technical team. You'll be fully trained to safely operate the machinery and supported in bringing your ideas to life.

Metal bending and fabrication equipment

Our metal bending and fabrication equipment will allow you to realise your designs through a range of metal forming processes.

Welding machinery

Use our top of the range welding equipment to construct multi-part assemblies from steel and a variety of other metals.

Haas CNC machining centre

The Haas Super Mini Mill is used to make components/parts from metals and some plastics.

Using a milling machine is one of the most commonly used processes in industry for machining parts to specific sizes and shapes. You may our HAAS machine to develop and design your projects.

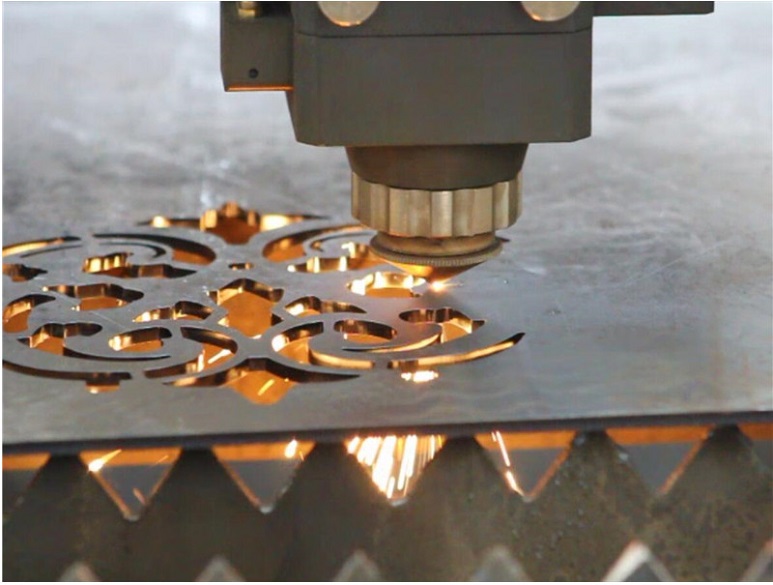

Laser cutting machines

You'll be able to work with our large and small format laser cutting machines to progress your designs in a range of materials.

Waterjet cutter

Waterjet cutting is one of the fastest growing major machine tool processes in the world and this £100,000 piece of equipment is able to cut almost any material to a depth of 150mm. If your project requires you to use the waterjet cutter, you'll be taught to operate this machine and supervised by expert technicians.

Plasma cutters

Plasma cutting is the process of cutting through materials with accelerated bursts of hot plasma. Supported by our Technical team, you can use our high-quality machine, which can cut metal from 0.5mm – 15mm.

Ajax Fusion part CNC lathe

The CNC lathe is used to make turned components and parts that are symmetrical around their central axis, from metals and some plastics.

You might be taught to use this machine for cutting, sanding, knurling, drilling, and deformation of metal based materials. You can use this equipment for metalworking, woodturning, metal spinning and thermal spraying.

Conventional machines

Alongside our CNC machinery, we also have a range of conventional machines that you'll use during your studies. These include the Colchester Student Lathe, which is used to make turned components and parts, that are symmetrical around their centre axis and our Bridgeport milling machine which is used to make components and parts from metals and plastics.

We also have two bench mounted drill machines, one pedestal drill, and one radial arm drill for producing holes, from 1mm diameter up to 50mm diameter, in metal and plastic parts.

Take a virtual tour

More like this

Prototyping workshops

Our prototyping workshops are the perfect place to test and develop your designs and products. You'll find student product designers, furniture designers and architectural designers in this space.

Wood workshop

For some projects that involve creating models from wood, you'll work in this space filled with the equipment and technical expertise required to support.

Model-making studio

You'll be able to develop your projects in this well-equipped space, facilitated with expert supervision from our workshop technicians. In here you'll find bandsaws, sanders, 2D and 3D hot-wire cutting and vacuum forming machinery, milling machines, lathes and drills.

3D-printing studio

In our 3D Printing facility, you'll be able to produce models on CAD stations and then send it to print for it to be manufactured.