BSc (Hons) Product Design students celebrate Hydro Aluminium Extrusion design competition awards

Nottingham Trent University (NTU) and Hydro Aluminium UK Ltd continued their long-established collaboration by inviting 58 BSc (Hons) Product Design students to visit their facilities in Tibshelf, Derbyshire and to take part in a competition to design a product that focused on the process of aluminium extrusion.

By Antonio Cuyas | Published on 12 October 2023

Categories: Student Showcase; School of Architecture, Design and the Built Environment;

BSc (Hons) Product Design students were challenged by Hydro to design a commercially viable product made from an aluminium alloy and manufactured via the extrusion process. The brief asked students to either design a completely new product or redesign an existing product. The designed product outcomes had to be technically feasible, sustainability focussed and commercially viable. Students were judged on the designed products marketability, sustainability and technical viability including design usability and manufacturability.

This year’s winners were Ethan Howard and James Shaw (Joint 1st Place & Gold Award Winners) and Zak Corbishley and Amy Rutherford (Joint 2nd Place & Silver Award Winners). Furthermore, Hydro also awarded four students Highly Commended Awards, these were awarded to Zachary Copeman, Charlie Edney, Tom Evans and Lewis Varrier.

During the competition, students were challenged to communicate the potential benefit of their product whilst accounting for the sustainable values of their designed solution and its environmental impact. To gain an understanding of the design process for an aluminium extruded product, Hydro’s design and manufacturing specialists provided expert lectures and resources to guide the students through the design process. Furthermore, students were provided with guided tours around a fully operational aluminium extrusion factory getting witness the entire manufacturing process from raw material through to final product manufacture, quality assurance testing and packaging/shipment.

This year students were also treated to an additional careers advice session by various Hydro staff on how they could progress into a role at Hydro or in the design / manufacturing sector. Hearing from Hydro employees, the students got to hear about their journey from completing their university studies through to undertaking numerous roles in the sector.

NTU BSc (Hons) Product Design Students experiencing a tour of Hydro’s aluminium extrusion site.

Dr Luke Siena, Lecturer in Product Design, who led the students throughout the project, said: “Our collaboration with Hydro Aluminium UK Ltd continues to provide students with a fantastic opportunity to gain work-like experience within a real-life industrial manufacturing environment. Our BSc Product Design students are lucky to be provided with a full behind the scenes tour and experience of an active manufacturing facility as well as getting to spend time with experts in the sector”.

“We are delighted that Hydro continues to provide their time and expertise by arranging talks for our students with industry experts, providing students with sample extrusions/tools, offering career advice as well as providing a tour of their manufacturing facility. Subsequently all our students responded enthusiastically to undertaking their aluminium extrusion focussed projects and produced some fantastic outcomes”.

Natalie Connor Compton, Hydro UK Marketing Manager added: “We are really proud of our relationship with NTU, and we thoroughly enjoy inviting the students to our Tibshelf site for workshops and site tours and then reading through all of their project work”.

“This year we were really impressed with the range of products designed that the students considered, and it was great to see how well they had used the technical information we had provided and how they had created products which reflected the sustainability impacts as well. Congratulations to the winners who we felt had created designs which were personal to them and that had a high level of creativity, expertise and understanding of their target markets”.

Winners of the main awards were awarded cash prizes ranging from £100-£250 based on the quality of their submissions.

NTU BSc (Hons) Product Design Students posing with their certificates.

Speaking about his experience taking part, gold award winner, Ethan Howard said:

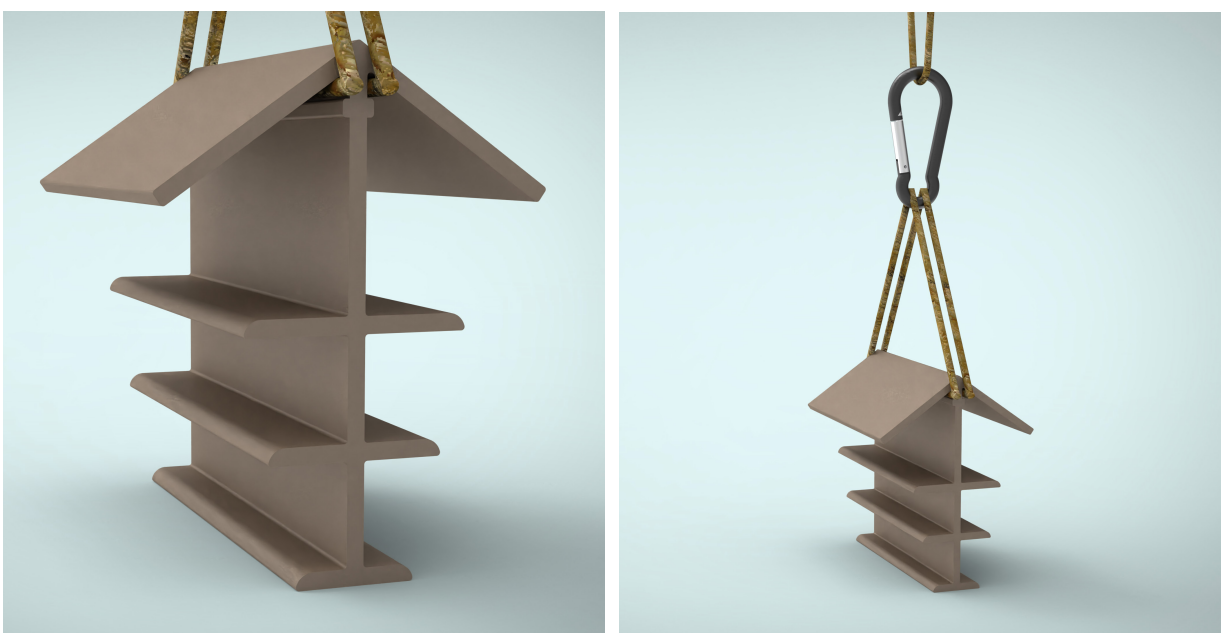

“Being a keen rock climber, I wanted to design a product which could be used to help climbers train and improve their strength. Many hangboards (training tools to help strengthen fingers and muscles used for climbing) are expensive and made from resins and plastics, meaning their manufacture has a negative impact on the environment. By using aluminium, which is infinitely recyclable and a much greener material, the environmental impacts of the product’s manufacture is much less. In addition to the manufacturing cost being lower, allowing the retail value of the product to be kept low”.

“This project was my first time designing within such strict parameters, this made the process challenging yet rewarding. The visit to the Hydro factory helped to develop my understanding of the aluminium extrusion process and I am very grateful for Hydro who hosted this competition.”.

Photo of Ethan Howard’s gold winning submission for the design of an aluminium extruded hang bar for rock climbers.

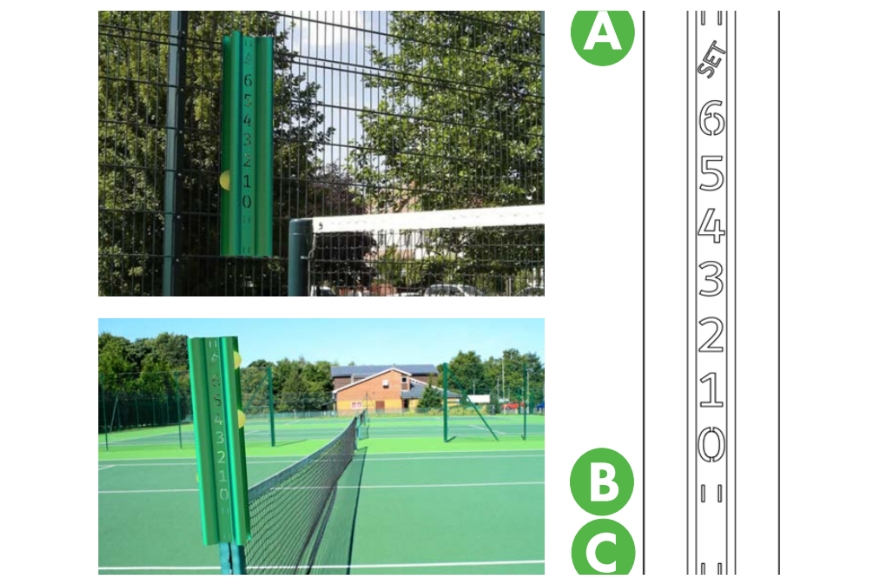

James Shaw was awarded a gold award for his design of an aluminium extruded tennis scoring system that attaches to tennis net poles. He explained his process and experience taking part:

“I chose to design a product based around tennis due to my previous career as a professional wheelchair tennis player, giving me the insights and contacts to get some very valuable research. This project was a really exciting challenge as it included a lot more manufacture constraints than I had previously experienced. During the first couple of weeks of the project we went to the Hydro aluminium extrusion facility which gave us all lots of information on the extrusion process, the possibilities of aluminium, and what it’s like to work with a live client”.

“My final design incorporates sustainability through the use of aluminium and reuse of old tennis balls to score tennis matches in a new way. Tennis within Great Britain is getting millions of pounds invested into it by its governing body, so a product that can be used for 10+ years in all weather conditions would be sought after; helping to drive in new tennis players and growing the sport of tennis”.

Photo of James Shaw’s gold winning submission, an aluminium extruded scoreboard attachment for tennis net poles.

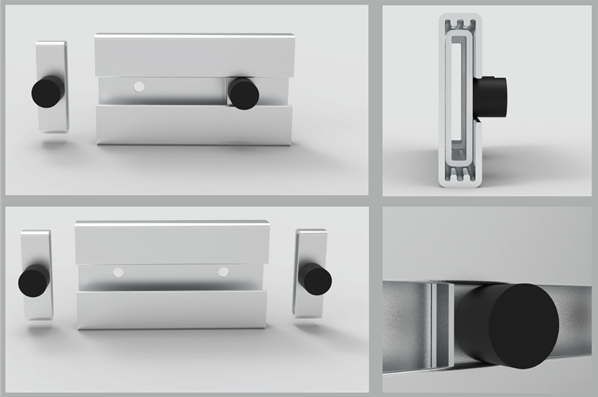

Any Rutherford, who was awarded a silver award, reflected on her experience:

“I decided to create a challenge focused design on my interest in music. During my research, I discovered that storing musical instruments, especially guitars with their different sizes and shapes, can be quite difficult, particularly in limited spaces”.

“This was my first time working with the limitations of a manufacturing process, and there were numerous intricate details that required careful consideration. The visit to the Hydro facilities provided me with a deeper insight into the production line and how the process works from start to finish. Receiving a silver award for my submission thrilled me and has boosted my confidence to explore topics beyond my comfort zone, whilst developing future product solutions for design briefs”.

Photo of Amy Rutherford’s silver award winning submission, an adjustable musical instrument wall mounting system.

Congratulations to all the students recognised in this years’ competition:

- Joint 1st Place (Gold Awards) - £250 Cash Prize Each: Ethan Howard & James Shaw

- 2nd Place (Silver Award) - £100 Cash Prize Each: Zak Corbishley & Any Rutherford

- Highly Commended Submissions: Zachary Copeman, Charlie Edney, Tom Evans and Lewis Varrier.