BSc (Hons) Product Design Students Triumph in Hydro Aluminium Extrusion Design Challenge

Nottingham Trent University (NTU) and Hydro Aluminium UK Ltd have maintained their long-standing partnership by inviting 55 BSc (Hons) Product Design students to their Tibshelf, Derbyshire facilities. The students participated in a competition centred around designing a product that focusses on the aluminium extrusion process.

By Ruth Melling | Published on 24 October 2024

Hydro tasked BSc (Hons) Product Design students with creating a commercially viable product using an aluminium alloy and the extrusion process. The brief allowed for the design of a new product or to redesign of an existing product. The final designs needed to be technically feasible, sustainability-focused, and commercially viable. Students were evaluated on the marketability, sustainability, and technical viability of their designs, including usability and manufacturability.

This year’s winner was James Cheetham (1st Place & Gold Award Winner) with Anel Nosinova and Nivedh Ian Sujith.

Collecting the runner up prizes (Joint 2nd Place & Silver Award Winners). Furthermore, Hydro also awarded five students Highly Commended Awards, these were awarded to Josh Abbott-Baptiste, Mervat Elderini, Otto Lehmann, Harry Pearson and Harry Scowcroft-Tay.

During the competition, students were tasked with demonstrating the potential benefits of their products while considering the sustainable values and environmental impact of their designs. To help them understand the design process for aluminium extruded products, Hydro’s design and manufacturing specialists offered expert lectures and resources. Additionally, students were given guided tours of a fully operational aluminium extrusion factory, allowing them to observe the entire manufacturing process from raw material to final product, including quality assurance testing and packaging/shipment.

Whilst on the trip students were also put through their paces with a quick design activity with the final session focussing on careers advice delivered by Hydro staff on how they could progress into a role at Hydro or in the design / manufacturing sector.

Dr Luke Siena, Lecturer in Product Design, who led the students throughout the project, said: “Our partnership with Hydro Aluminium UK Ltd offers students an incredible opportunity to gain practical experience in a real-world industrial manufacturing setting. Our BSc Product Design students benefit greatly from behind-the-scenes tours and hands-on experiences at an active manufacturing facility, as well as interactions with industry experts.”

“We are thrilled that Hydro continues to invest their time and expertise by organizing talks provided by their industry professionals, providing sample extrusions and tools, offering career advice, and giving tours of their manufacturing facility. As a result, our students gain a huge amount of insight and always become even more excited by their aluminium extrusion projects for which they continue to produce fantastic outcomes.”

Natalie Connor Compton, Hydro UK Marketing Manager added: “We have really enjoyed continuing our relationship with NTU this year. The students who visited us at our Tibshelf site were all enthusiastic and engaging and we enjoyed showing them around our facilities and explaining the extrusion and recycling processes. The projects we received this year were ambitious and creative and we are happy to see so much talent and lots of ideas. Well done to this year’s winners, who showed great levels of knowledge regarding aluminium extrusion and used this to create innovative and sustainable designs.”

Winners of the main awards were awarded cash prizes ranging from £100-£250 based on the quality of their submissions.

Winners Project - James Cheetham

Speaking about his experience taking part, gold award winner, James Cheetham said:

“I chose to design my project focusing on renewable energy generation. Wind energy is being increasingly implemented around the world, so it felt suitable to target my research and design into this area. I realised current turbines for household and residential use have a lot of weaknesses so by developing a version using extruded aluminium, the cost, longevity, looks and sustainability can all be improved and make residential turbines far more viable.

My experience undertaking the Hydro Project has been really positive, and having additional challenges such as considering manufacturing constraints and the technicalities involved has allowed me to improve and develop as a designer.”

Runner Up Project - Anel Nosiniova

Silver Award winner Anel Nosinova shared her thoughts:

“I focused on solving the problem of kitchen utensils' storage and drying, which often goes neglected in compact accommodations. Unlike plastic alternatives, this organiser is compact, secure, and durable, providing both storage and drying space to prevent hygiene issues.

The design emphasizes sustainability with features like design for disassembly, the use of recyclable aluminium alloy 6063, and consumer education on recycling. The Mix&Match marketing strategy allows users to customize their organisers, ensuring a minimalistic and individualized approach suitable for Motorhomes and other types of compact accommodations. I am immensely grateful to Hydro for providing me with this incredible opportunity.”

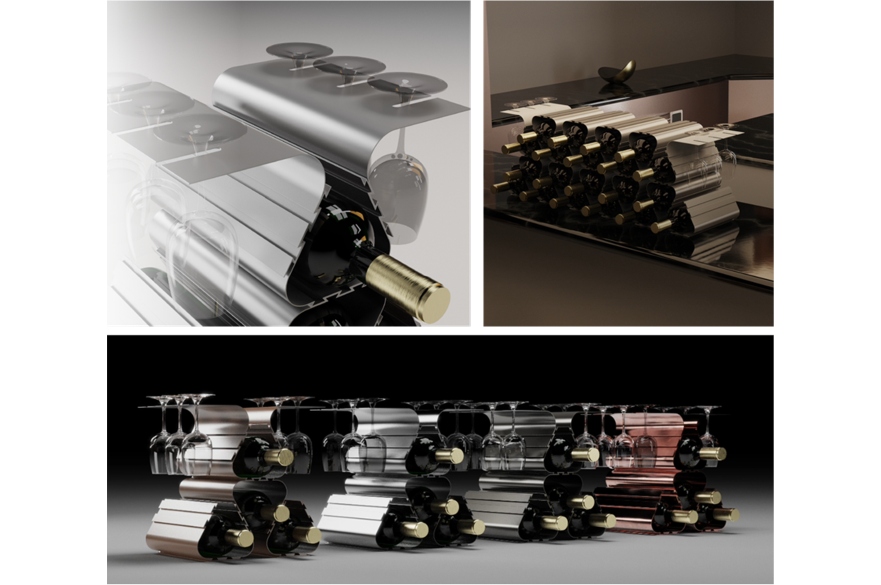

Runner Up Project - Nivedh Ian Sujith

Silver Award winner Nivedh Ian Sujith also reflected on his experience:

“My initial research led me to focus on the kitchen storage market, aiming to optimally utilize the material's qualities by implementing a slotting feature that would make the product modular and scalable increasing its potential applications. The development process was very insightful, leading to a commercially viable product that optimally uses the extrusion process.

"Working with Hydro was a valuable experience; visiting the Tibshelf facility and seeing the extrusion processes firsthand gave me a profound appreciation for aluminium’s potential in product design. This hands-on experience enriched my knowledge and appreciation for the material’s versatility and environmental benefits deepening my passion for sustainable and innovative design.”

Congratulations to all the students recognised in this years’ competition:

- 1st Place (Gold Award) - £250 Cash Prize: James Cheetham

- 2nd Place (Silver Awards) - £100 Cash Prize Each: Anel Nosinova & Nivedh Ian Sujith

- Highly Commended Submissions: Josh Abbott-Baptiste, Mervat Elderini, Otto Lehmann, Harry Pearson and Harry Scowcroft-Tay.